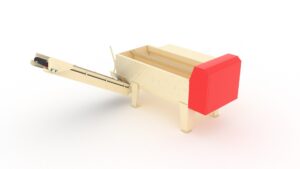

Jumbo bag filling machine

Jumbo Bag with Continuous Bag Exchange Mechanism

Jumbo bag filling machines play a vital role in the packaging industry for powdered and granular materials, including mushroom casing soil and similar products. The jumbo bag filling machine, equipped with a reversible conveyor mechanism (left-turn and right-turn) and human operator coordination, enables continuous bag filling without stopping the production line. In this system, the replacement of filled bags occurs simultaneously with the filling process of another bag, enhancing efficiency and reducing downtime.

Main Components of the Machine

- Main Feed Conveyor: Transfers materials from the storage tank to the distributing conveyor.

- Reversible Distributing Conveyor: Can switch between left-turn and right-turn directions, directing materials to the left or right bags.

- Filling Guide Hopper: The jumbo bags are secured around it to ensure uniform filling.

- Manual Control System: Includes conveyor direction-switching buttons and an emergency stop function for the operator.

Operation Process

- The operator sets the conveyor to right-turn mode, and materials are poured into the right-side bag until it is completely filled.

- Immediately after filling the right bag, the operator switches the conveyor direction to left-turn, directing materials to the left-side bag.

- While the left bag is being filled, the operator and forklift remove the filled right bag and replace it with an empty one.

- Once the left bag is full, the conveyor switches back to right-turn mode, and the process repeats.

System Advantages

- Reduced Downtime: Continuous filling and simultaneous bag replacement.

- Lower Cost: Compared to fully automated systems.

- Flexibility: Manual adjustment for different materials.

- Easy Maintenance: No need for complex sensors or control systems.

For free consultation and detailed technical information, contact our sales experts.

-

Jumbo bag filling machine

-

Machine's dimension 6 × 2 × 6 m

-

Electricity 3 Phases

-

Electricity consumption 13.5 kW

-

Machine Mechanisms Electronics, mechanics, hydraulics

-

Bag Dimensions 90 × 90 × 110 cm (customizable)

-

Capacity 20 to 24 bags per hour