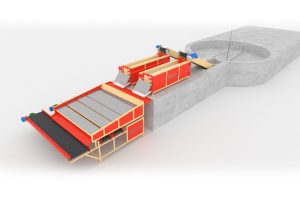

Carrot washing & sorting machine

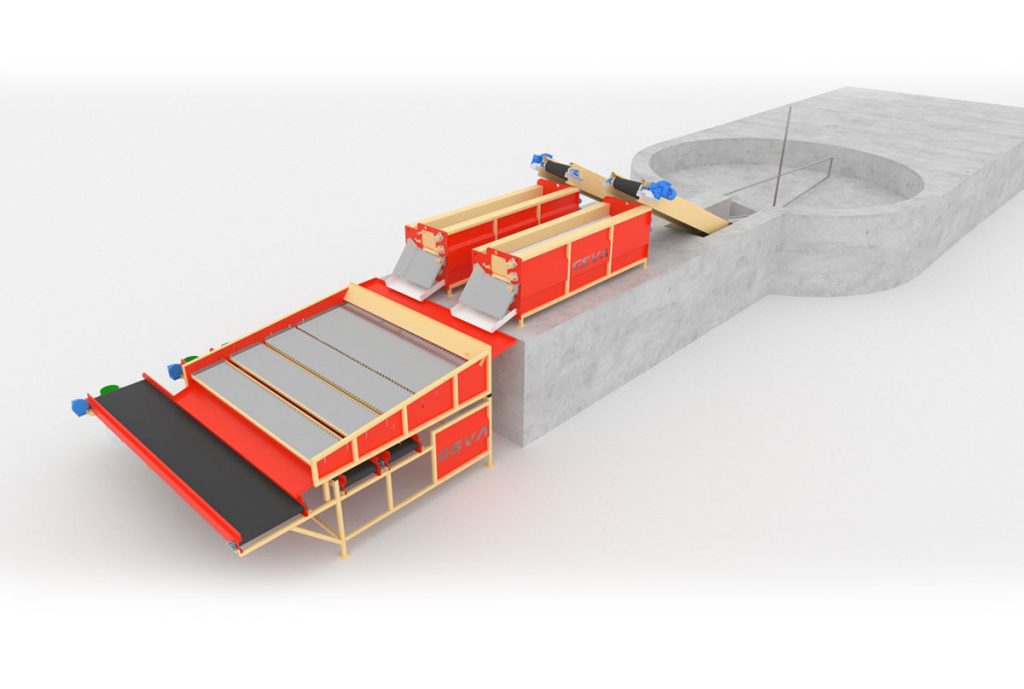

A fully mechanized and automatic line of carrot washing and sorting machines in three sizes with the ability to adjust the desired size. All washing steps, including a rotating basin for soaking carrot mud, separating mud by brushing, spraying water, automatic separation based on different and adjustable sizes, and finally transfer for basketing or packaging, are included in this washing line.

Carrot washing & sorting machine, manufactured by Golmehr Sana't ValiAsr co.

Carrot Washing and Sorting Machine: An Advanced Solution for Carrot Processing and Sorting

In the food and agricultural industries, processing fresh produce such as carrots requires precision, speed and high quality. The Carrot Washing and Sorting Machine is an advanced, automatic system specifically designed for washing, cleaning and sorting carrots. Using modern technologies, this machine optimizes the washing and sorting process and provides a high-quality product ready for packaging and distribution.

How the carrot washing and sorting machine works

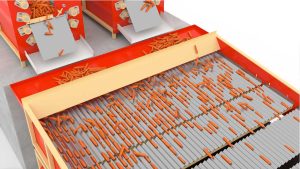

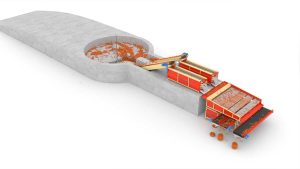

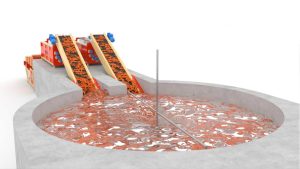

Primary Washing Tank::

The carrots are placed in a circular basin of water that is rotating. This rotation causes the carrots to move slowly through the water, removing dirt and surface contaminants.

The water flow in the basin is designed so that the carrots are completely immersed in the water and the washing process is carried out evenly.

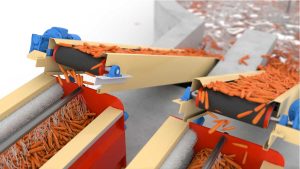

Transfer to the Secondary Washing Section::

After the initial wash, the carrots are transported by a conveyor belt from the basin to the second washing section.

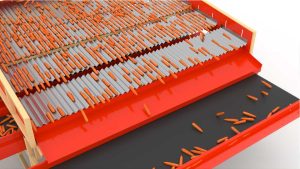

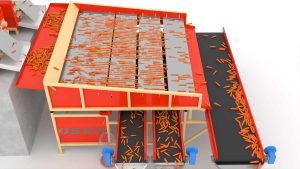

In this section, the carrots move through several rotating cylindrical brushes. These brushes are constantly rotating and, together with the water, thoroughly clean the carrots.

The brushes are designed to remove residual dirt in the best possible way.

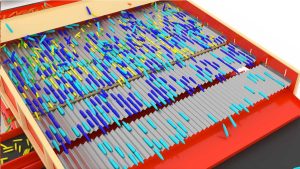

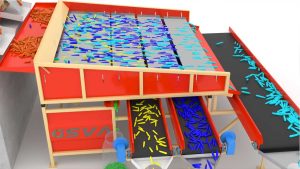

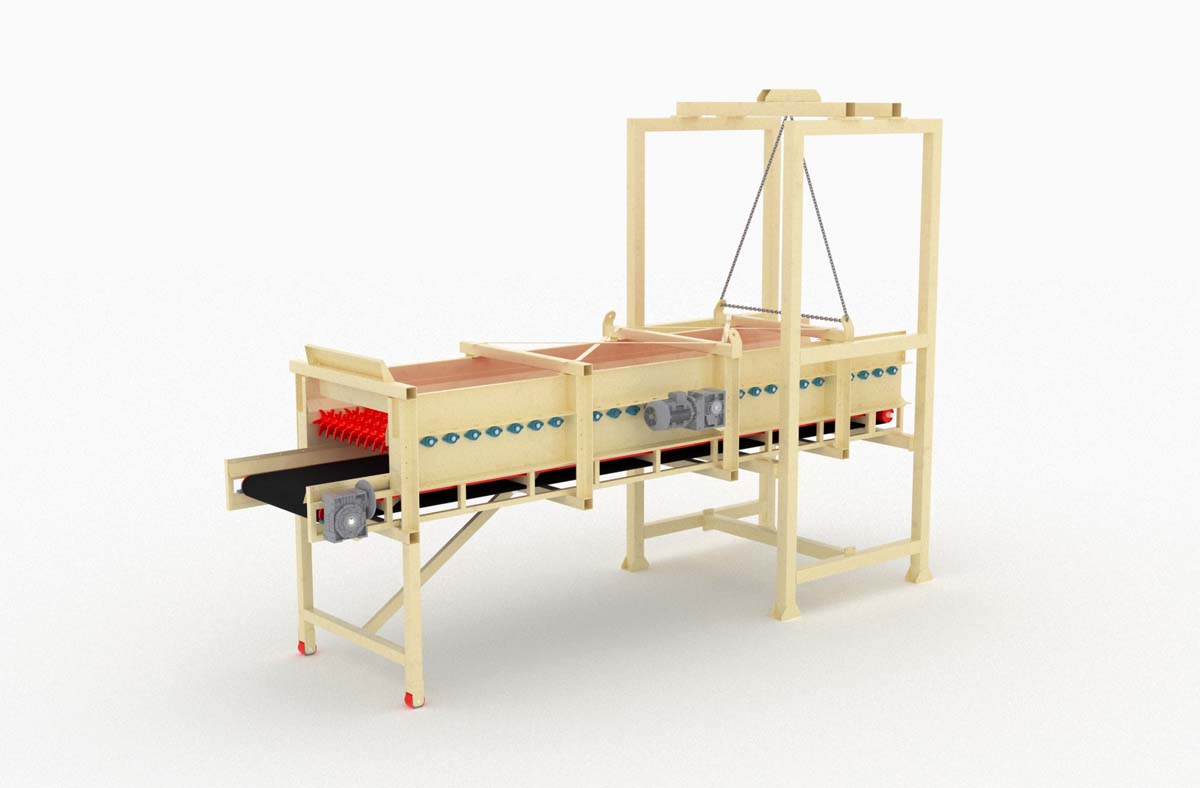

Sorting Machine::

The cleaned carrots are poured onto the sorting machine. This machine uses a vibrating sliding plate mechanism and outlet valves along the way to sort the carrots by size.

The sorting machine is equipped with multiple exit gates, each corresponding to a specific size of carrots. Depending on the size of the carrots, they are placed on separate conveyor belts.

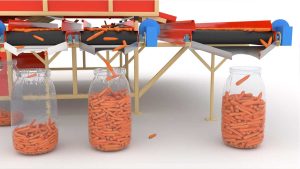

Final packaging::

The sorted carrots are transported via conveyor belts to the packaging section.

At this stage, the carrots are automatically or semi-automatically placed into bags, boxes, or other packaging containers and are ready to be shipped to market.

Benefits of carrot washing and sorting machine

High speed and accuracy: This machine is capable of washing and sorting a large volume of carrots in a short time.

Reducing labor costs: By automating the washing and sorting process, the need for human labor is reduced.

Improving product quality: The use of cylindrical brushes and advanced sorting systems increases the final quality of the product.

Flexibility: The machine is adjustable for sorting carrots of different sizes.

Device applications

Food industry: For the preparation of fresh, frozen or processed carrots.

Agriculture:: For post-harvest processing of products and increasing added value.

Packaging: To prepare carrots for packaging and distribution to the market.

Conclusion

Currently, carrot washing and sorting machines have become a necessity for farmers who are looking to increase productivity, reduce costs, and improve the quality of their products. Using this machine, the process of washing and sorting carrots is carried out fully automatically and with high accuracy, and the final product is supplied to the market with the desired quality. This machine not only reduces processing time, but also fully complies with hygiene and quality standards.

-

Carrot washing and sorting machine information

-

Tonnage per day (wash and sort) 50 tons a day

-

Machine Mechanisms Hydraulics, Electronics and Mechanics

-

Electricity required 3 Phases

-

Kind of sizing 4 different sizes

-

Capacity of washing tank 1.5 m3