1 ton corn silage packaging machine

(دستگاه بسته بندی ذرت علوفهای 1 تنی) دستگاه بسته بندی علوفه ذرت یک تنی بدلیل مهر و موم عالی، از ورود هوا و رطوبت جلوگیری کرده و فرآیند تخمیر به درستی انجام می دهند. بستههای یک تنی، حمل و نقل و ذخیرهسازی علوفه آسانتری دارند و به راحتی با استفاده از ماشینآلات کشاورزی جابجا میشوند . این بستهها به دلیل حجم بزرگتر، نیاز به "مواد اولیه بسته بندی " کمتری دارند. در نتیجه هزینه نهایی کمتری دارند که باعث شده دامداری های صنعتی تمایل بیشتری نسبت به خرید این نوع علوفه بسته بندی شده داشته باشند.

What kind of fodder does the 1 ton corn fodder packaging machine pack?

Among the materials that can be packaged with this machine (1 ton corn silage packaging machine) are corn silage, sugar beet silage, sugar beet pulp, sugarcane bagasse, filter cake, sugarcane sieve chopper, agricultural waste in general, and similar materials.

.

-

Information about the 1 ton corn silage packaging machine

-

Type of Packaging 1 ton packaging

-

Required force to carry 90 hp

-

Package tonnage (per hour) 40 ton

-

Machine Mechanisms Hydraulics, Pneumatic, Mechanics and Electronics

-

Electricity Consumption 42 kw

-

Air compressor 80 لیتر

-

dimensions of machine L=1200 W=330 H=380

-

Total weight of machine 10.3 ton

-

package size cylinder size 120 *120

-

package weight 400-1200 kg

-

Transporting power Electro gearbox & Hydro gearbox

-

Control system Touch

-

nylon type on the first stage Network or polyethylene film or stretch film

-

nylon type on the first stage width 125 cm

-

Nylon's type of the Second stage Stretch film

-

Nylon's type of the Second stage width 75 cm

Gallery

3D

بزودی

Video

Device introduction:

The one-ton corn silage packaging machine of Golmehr Sanat Valiasr Company is one of the most advanced and efficient machines in the agricultural industry, designed for corn silage packaging using modern technologies. This machine is capable of packaging packages with various weights between 400 kg and 1200 kg and shows unparalleled performance.

This machine is made of a durable body that uses stainless steel to prevent corrosion and rust in various conditions. As a result, the useful life of the machine is significantly increased. The machine operates automatically and only requires an operator to monitor the correct operation of the machine.

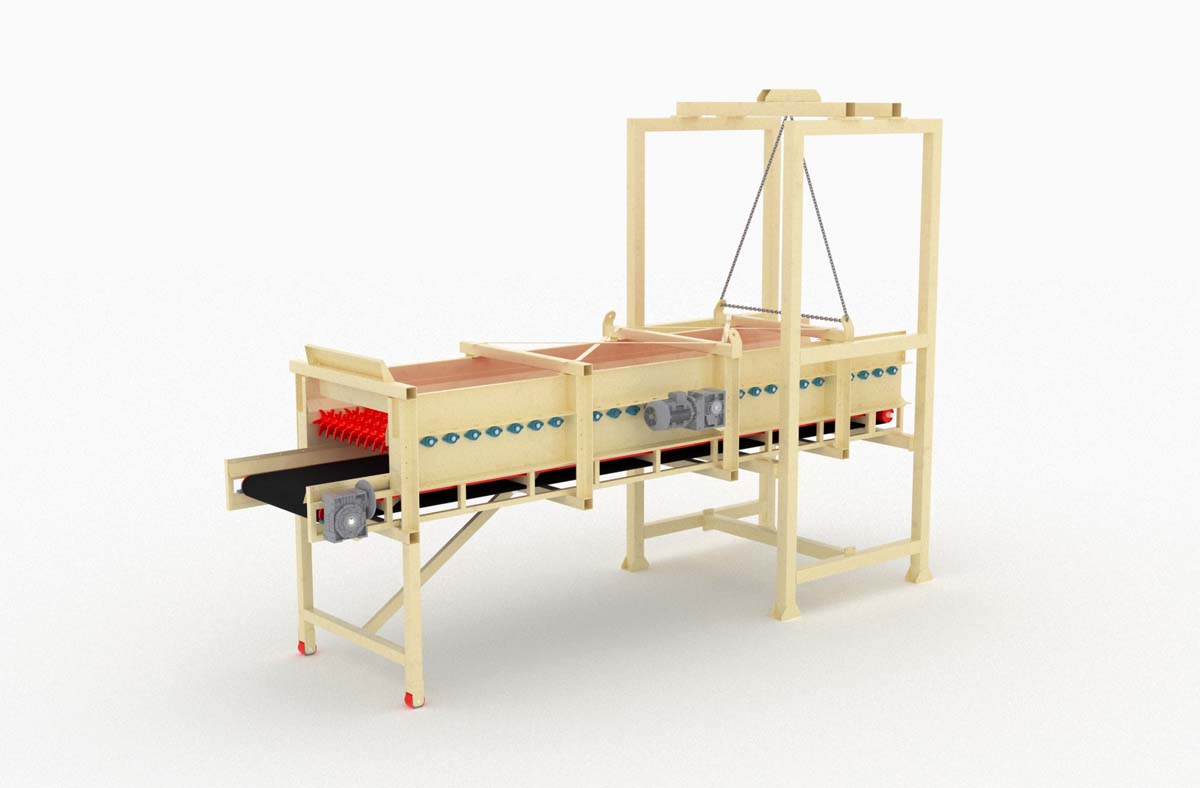

Main components of the 1 ton corn silage packaging machine:

The corn silage packaging machine consists of various important components, each of which plays a vital role in the packaging process. In this section, we will describe the main components of the machine and their features:

Hopper (Forage Storage): The hopper acts as a temporary forage storage source.

نوار نقاله انتقال:

نوار نقاله انتقال وظیفه جابجایی علوفه از هاپر به قسمتهای بعدی دستگاه را بر عهده دارد. این نوار نقاله علوفه را به محفظه فشردهسازی (چامبر) منتقل میکند.چامبر (محفظه فشردهسازی):

چامبر دستگاه بخش اصلی فشردهسازی علوفه است. در این بخش، علوفه وارد محفظه میشود و تحت فشارهای هیدرولیکی چرخش نوار منژیت قرار میگیرد. این سیستم باعث میشود که حجم علوفه کاهش یافته و به شکلی استوانه فشرده شده درآید که به راحتی قابل بستهبندی باشد.سیستم پیچیدن سلفون یا تور (مرحله اول):

سیستم پیچیدن سلفون یا تور یکی از اجزای برجسته دستگاه است که بستههای علوفه را محافظت میکند.پس از فشردهسازی علوفه در چامبر، سلفون یا تور ابتدا بهطور محکم به دور بسته پیچیده میشود تا بسته علوفه در حین جابجایی به مرحله بعد از هم نپاشد.نوار نقاله کف:

پس از فشردهسازی علوفه در چامبر، نوار نقاله کف وظیفه انتقال بستههای فشردهشده به قسمتهای بعدی دستگاه را بر عهده دارد. این نوار نقاله بهصورت اتوماتیک بستهها را از چامبر خارج کرده و به بخشهای نهایی هدایت میکند.Complex sulfone or black (step 2):

After the packages are transferred to the floor conveyor, the cellophane wrapping system automatically re-wraps additional layers of cellophane around the packages until they are completely wrapped.

Cut off excess cellophane:

The cutting system automatically cuts off excess cellophane and holds the end of the cellophane ready to start the next package.

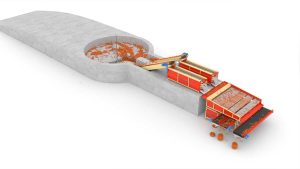

How the device works:

The operation of the corn silage packaging machine is fully automatic, which is explained step by step in this section:

Forage entering the hopper:

First, the silage enters the hopper and is stored in this section. The hopper plays an important role in providing the machine with fodder.Transferring fodder to the conveyor:

The feed is uniformly transferred from the hopper to the conveyor belt. The conveyor belt directs the feed towards the chamber.Compression in the chamber: The fodder enters the chamber of the machine. In this section, the hydraulic systems of the rotating movement of the mange are used to compress the fodder. This process causes the fodder to be ready for packaging with high density and in a smaller volume.

Wrapping with cellophane or net (first stage): After the forage is compressed in the chamber, the wrapping system automatically wraps cellophane or net around the forage bales. These layers are tightly wrapped around the bale in several layers.

Transfer to floor conveyor: The compressed packages are automatically transferred to the floor conveyor, which is responsible for moving the packages to the next parts of the machine.

Complex sulfone or black (step 2):

After the package is transported by the floor conveyor, the cellophane wrapping system automatically wraps additional layers of cellophane around the packages to completely seal them and completely block the penetration of air, moisture, etc.Cut off excess cellophane:

The cutting system automatically cuts off excess cellophane and guides the packages out of the machine.

Advantages of the device:

High speed and efficiency: This machine is capable of packaging up to 40 tons of fodder per hour, depending on the dryness or moisture of the fodder. The high speed of this machine increases productivity and reduces the time required for packaging.

Excellent compression: The chamber system and hydraulic compression power of the machine produce high-density bales that preserve forage quality and reduce storage space.

Durable and long-lasting body: The use of stainless steel in the construction of the device body ensures that this device operates without rust or damage, even in harsh working conditions. This feature increases the life of the device and helps producers and livestock farmers to use their device for a long time.

Cost savings: Due to the domestic production of the device, its price is approximately one third of European models. This feature allows farmers and livestock keepers to significantly reduce their costs.

Automatic system and reduced need for manpower: The device operates automatically and only requires one operator to monitor. This feature reduces manpower costs and increases productivity.

Automatic system and reduced need for manpower: The device operates automatically and only requires one operator to monitor. This feature reduces manpower costs and increases productivity.

Using modern technologies and advanced systems, the Golmehr Sanat Valiasr corn silage packaging machine is a highly efficient and cost-effective option for packaging corn silage and other forages. With excellent compression, high speed, and a durable body, this machine is an ideal choice for livestock farms and farmers looking to increase productivity and reduce production costs.