Vacuum cooling machine - vacuum cooling

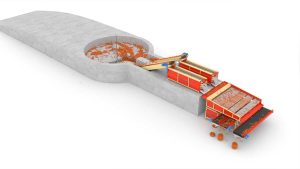

Vacuum cooling machine (Vacuum Cooling) is a cooling technique used to reduce the temperature of agricultural products such as vegetables, flowers, and fruits after harvest. This method is especially useful for temperature-sensitive products such as leafy vegetables or flowers.

[Company Name] is the manufacturer of the highest-quality vacuum cooling devices in Iran, complying with the strictest global standards and holding CE certification for this device.

In this process, the product is placed under negative pressure (vacuum), so that the water inside it evaporates. This evaporation takes a lot of energy from the product, thus reducing its temperature. In fact, when the ambient pressure decreases, the boiling point of water also decreases, causing the moisture in the product to evaporate more quickly. This action reduces the temperature of the product without the need for ice or mechanical refrigeration.

How it works:

- Creating a vacuum: Products that need to be cooled are placed inside a vacuum chamber.

- Pressure reduction: By creating negative pressure inside the chamber, the boiling point of water decreases and the water in the product evaporates quickly.

- Evaporation and cooling: Evaporation of water from inside the product reduces its temperature.

Advantages:

- High speed: The cooling process is completed in a short time.

- Maintaining quality: Due to the rapid temperature drop, spoilage and undesirable changes in product quality are prevented.

- Moisture retention: Because this is the process of evaporating water from the surface of the product, the internal moisture of the product is maintained and prevents it from drying out.

- Less changes in product quality: Because evaporation is rapid, there are fewer negative effects on product quality, such as changes in color and texture.

Applications:

- This device is very useful for cooling products such as vegetables, including lettuce, cabbage, leafy greens, and flowers.

-

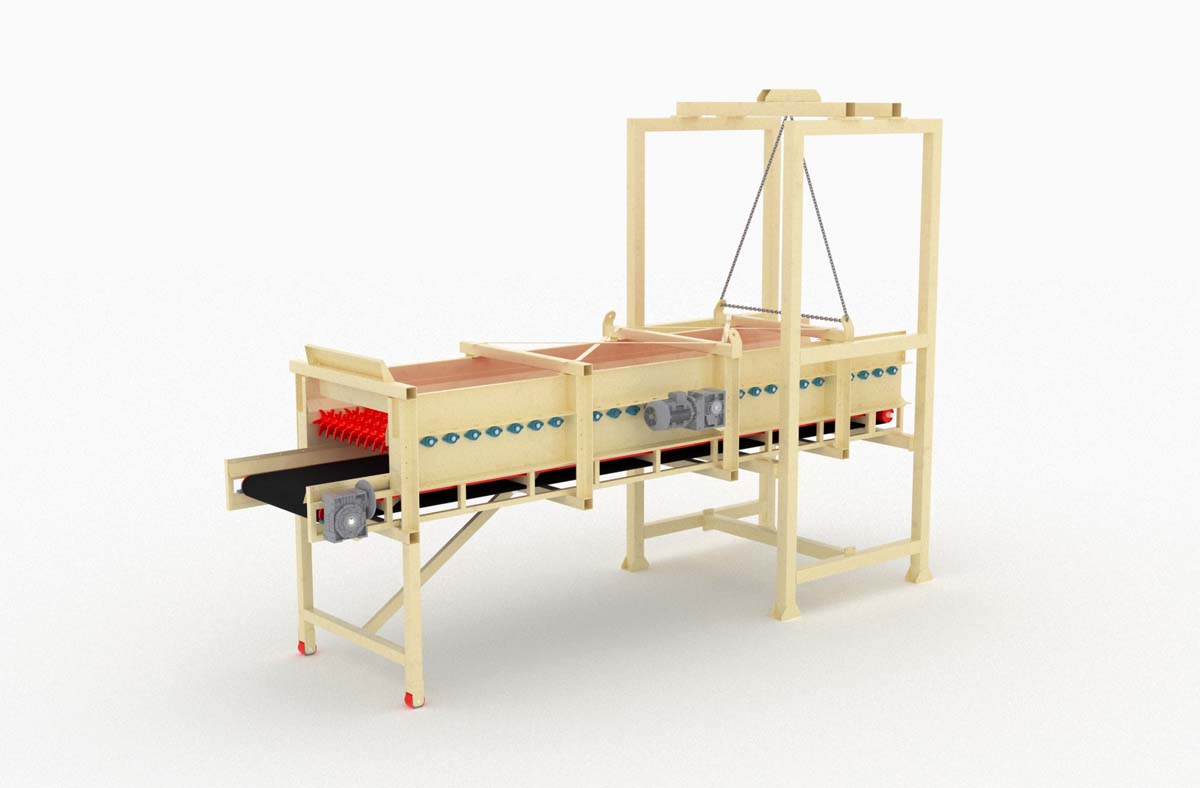

4-Plate Vacuum Cooling Machine

-

Vacuum chamber dimensions 2.5m * 1.4m * 5m

-

Overall dimensions of the device 10m * 2.2m * 2.8m

-

Nominal capacity of the product 2000 kg/cycle

-

Cooling cycle time 20 - 25 minutes

-

Maximum current consumption 164 A

-

Maximum power consumption 80 kw

-

Vacuum pump power 15 kw

-

Approximate weight 15000 kg

-

Product inlet temperature max 35°C

-

Final product temperature 2°C تا 6°C

-

Screen 10 inch touchscreen